© youplate.co.uk 2019 For more information, please see site Terms & Conditions -

View Cart

View Cart

MAINLAND UK ONLY

MAINLAND UK SUPPLY ONLY -

This page will hopefully offer a little advice and assistance with your electroplating projects. If you have any pictures of work that you’d like to share, by all means send them in to us and we will share them with the world! If we have any hints and tips which may prove useful we’ll have it here. Remember that if you’ve something useful to share with us, please get in touch and we will be happy to pass your tips on within these webpages.

Keep checking back for more pictures and tips.

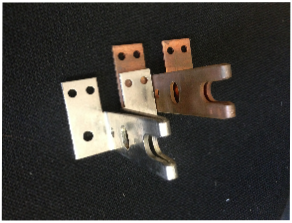

A test component supplied by a customer, the part on the right is a copper bracket, dirty and un-

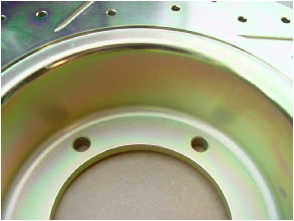

Although the part above is a large brake disc, plated by an industrial electroplater, it perfectly demonstrates the attractive yellow colour attainable from our yellow passivate for zinc plating.

WOW! What a difference!

The picture on the left shows an old brass handle which really was a bit of a state! This was found in our lab, rotting away, so we thought we’d show our bright copper solution at work.

How was this done?

We used an acid dip to remove the oxidation, swilled and then copper plated at 1V (0.8A) for 12 minutes.

A high build copper deposit would need a LOT of copper and a LOT of skilled polishing to get anywhere near this bright. Our bright copper solution, using the correct PDO copper anodes gives a really nice finish with very little effort!

The brass handle did not look nice at all and had no usable patina. It’s a cast piece, so is never going to look great without plating anyway so we electroplated this and it’s now ready for either patina application or even a nice bright nickel finish.

Here’s another old brass handle that we’ve plated using our “high build” dull acid copper solution. We’ve plated for some time here to get enough deposit to allow effective polishing. Note the dull colour compared to the bright deposit above.

WE WANT YOUR PHOTOGRAPHS!

We are are looking for your electroplated work -

We’ve been testing our new HyBlack, cold chemical blacking solution -

Heres our Bronzing Solution which gives a gives a beautiful antique look to brassware. This is a very common finish and can be seen in many hardware stores around the country.

Used on raw brass, these products are used at dilutions from between 1:1 and 1:4 with water -

| Customer Projects |

| Pickling |

| Cleaning Products |

| Passivates |

| Zinc Plating Products |

| Zinc Plating User Guide |

| Zinc Plating Process |

| Nickel Plating Products |

| Nickel Plating Salts |

| Bright Nickel Plating |

| Zincate |

| Etching and Anodising |

| Anodising Process |