© youplate.co.uk 2019 For more information, please see site Terms & Conditions -

View Cart

View Cart

MAINLAND UK ONLY

MAINLAND UK SUPPLY ONLY -

Chemical Blackening has been a metal finishing process used for decades. A popular process for moving parts and gun parts alike, the blackening process is traditionally performed in very hot caustic solutions. The product, whilst inexpensive to buy is very expensive to operate when considering the tanks required and in particular the heating costs to get solutions up to temperature and importantly to keep the temperature high.

Now we are happy to announce our new HyBlack chemical blacking process which requires no heating and operates effectively at room temperature. Simply dilute in water to operate.

HyBlack - Chemical Blackening Solution

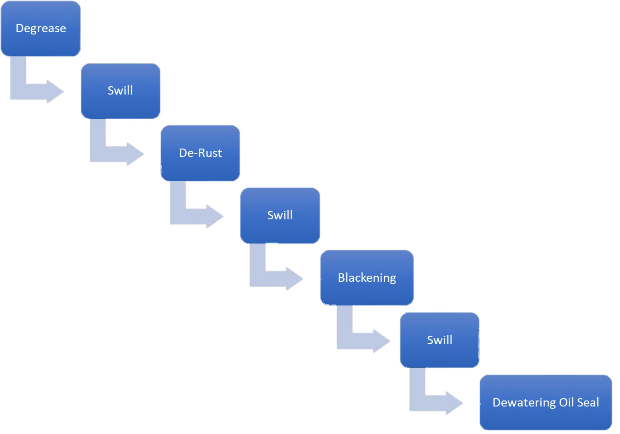

Through development and constant testing, we have been able to produce a blacking solution we are proud to offer both industrially and to the hobby metal finisher. The blacking process is easy to operate and preparation is just like all metal finishing processes for mild steel; de-

Our solution can be used at concentrations as low as 10% but we recommend operating at 25 -

De-watering Fluid - DWF 2005

Many metal finishing treatments require final stage immersion in a rust preventative. DWF 2005 is our market leading dewatering fluid used across the country industrially as a post treatment for chemical blacking. Used as supplied, the solution rejects water and therefore removes any remaining droplets from your work, leaving the active ingredients on the surface. After treatment the surface may be left wet or excess wiped off. A traditional finish to chemical blacking.

1 litre -

5 litres -

500ml -

250ml -

1 litre -

5 Litres -

100ml -

HyBlack, Cold Blackening Process Chart

| Customer Projects |

| Pickling |

| Cleaning Products |

| Passivates |

| Zinc Plating Products |

| Zinc Plating User Guide |

| Zinc Plating Process |

| Nickel Plating Products |

| Nickel Plating Salts |

| Bright Nickel Plating |

| Zincate |

| Etching and Anodising |

| Anodising Process |