© youplate.co.uk 2019 For more information, please see site Terms & Conditions -

View Cart

View Cart

MAINLAND UK ONLY

MAINLAND UK SUPPLY ONLY -

This page is especially for you to share your hints and tips as well as to show off work you are proud of (or not as the case may be). We are happy to devote this page to anything you’d like to share so drop us a line at mail@youplate.co.uk and we will also pop them on to our Facebook page too!

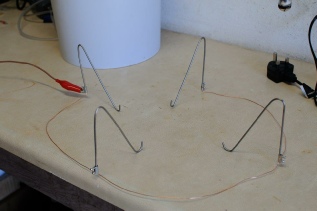

George’s tip for connecting anodes, titanium wire and copper wire.

It’s important to remember that copper wire used to connect anodes should not be immersed in your plating solution. Here our customer has shared how he has managed to connect his zinc anodes to titanium wire and in turn connect his titanium to his copper wire and power source.

Starting by drilling a hole in the zinc anode and then using an electrical connector block, George has made a great link for linking his anode line. By stripping (carefully) a connector from the plastic housing using a sharp utility knife, the connector parts can be used first to connect the titanium and then the copper wire. On the right we see Georges final set up. It is feasible to link all anode points in a complete circle. What a simple but brilliant solution! Thanks to George Munro for this great tip.

Our customer Ian, sent these pictures in to us. "They were part of the toolkit in 1920-

It’s always great to see results from our customers and Ian Oliver sent us these pictures of his very nice foot pump. We agree with Ian that it was a job worth doing and he’s certainly got a pleasing result. We are glad he’s happy. Home plating can be very satisfying indeed.

Remember we want to see your successes so that we can share them here online. Don’t be afraid to share your disasters too!

Here’s a selection of work from Toby. We’re very impressed with these parts! There’s a range of sizes here on display and the fact that even the larger parts are looking so nice is testament to quality of work. Experience helps a great deal. Toby has had a few issues but clearly is getting along great. Most of these parts are in our yellow passivate but there’s a nice example of the clear (blue) there too. Thanks for the pictures Toby! We’re always glad to hear how people are doing!

Before….

….And….

….After

Alwyn produces some really nice work here; plating bright zinc. We were really pleased to hear back with some pictures of some of his work and he was happy for us to share them here. We are sure you will agree that the results are really nice!

William was kind enough to send us some photographs of his work and we’re happy to share too! He’s another happy customer of our TriFin Y, trivalent yellow passivate!

| Customer Projects |

| Pickling |

| Cleaning Products |

| Passivates |

| Zinc Plating Products |

| Zinc Plating User Guide |

| Zinc Plating Process |

| Nickel Plating Products |

| Nickel Plating Salts |

| Bright Nickel Plating |

| Zincate |

| Etching and Anodising |

| Anodising Process |