Zinc Plating

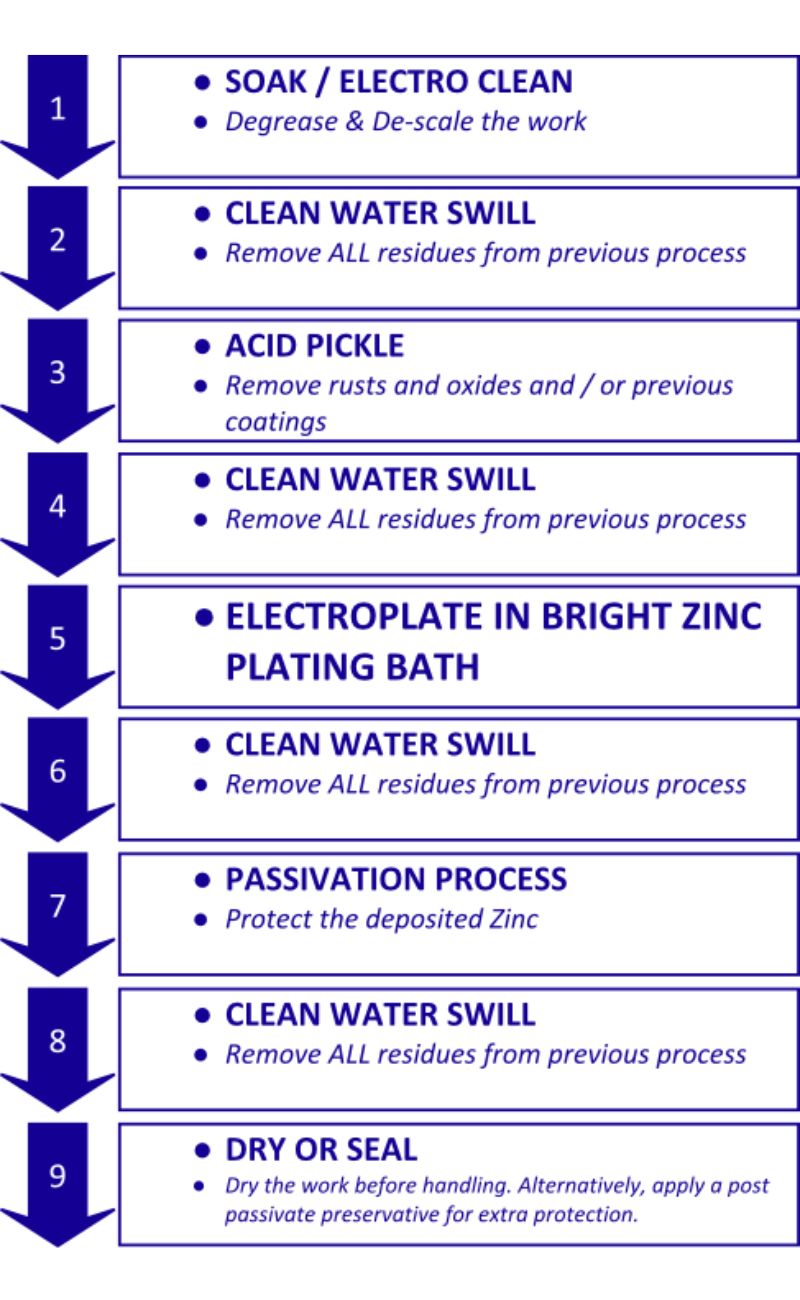

Problems with electroplating are often attributed to poor cleaning and surface preparation, so it’s essential to get it right!

Zinc is used in electroplating as a sacrificial coating to protect the underlying base material. Although zinc plated components are protected by the zinc coating, it is not the covering itself that protects underlying materials.

Due to electro-chemical reactions, it is the zinc which corrodes preferentially to the underlying material. Whilst being primarily used as a functional deposit, electroplated components can also be decorative and is far less stressful on components than the hot-dip galvanising alternative. Electro-deposition provides a thin coating that is easily controlled, which does not damage fine, machined parts and does not fill up slots and screw holes or obliterate threads and other fine details of work.

As an addition measure of protection, zinc plated work can be passivated to withstand conditions of raised humidity.

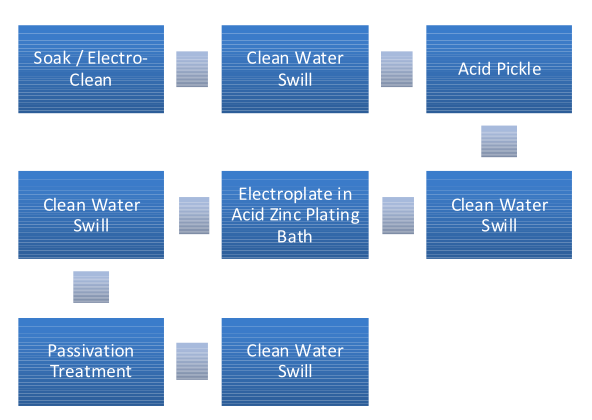

A typical process when zinc plating:

Zinc related products

-

Zinc Plating

Zinc plating (electroplating) process chemistry.

products

Quality is key

Whatever your work, you will need quality products. All of our products are industrial quality and supplied to industrial platers around the country. Whether you want to make your own solutions at home or buy ready to use products, there is definitely something we can help you with. Our experience and industrial expertise will help you gain the most out of your plating process and whether you are an absolute beginner or an accomplished hobbyist, we can offer second to none service and quality, get in touch if you have any questions or add our user guide to your basket.

Zinc plating process guide.

Contact us

Whilst there is a lot of information available online, we will try not to overload users of this web site with information which may not always be needed, so if there is a question you may have regarding you electroplating, please feel free to contact us.