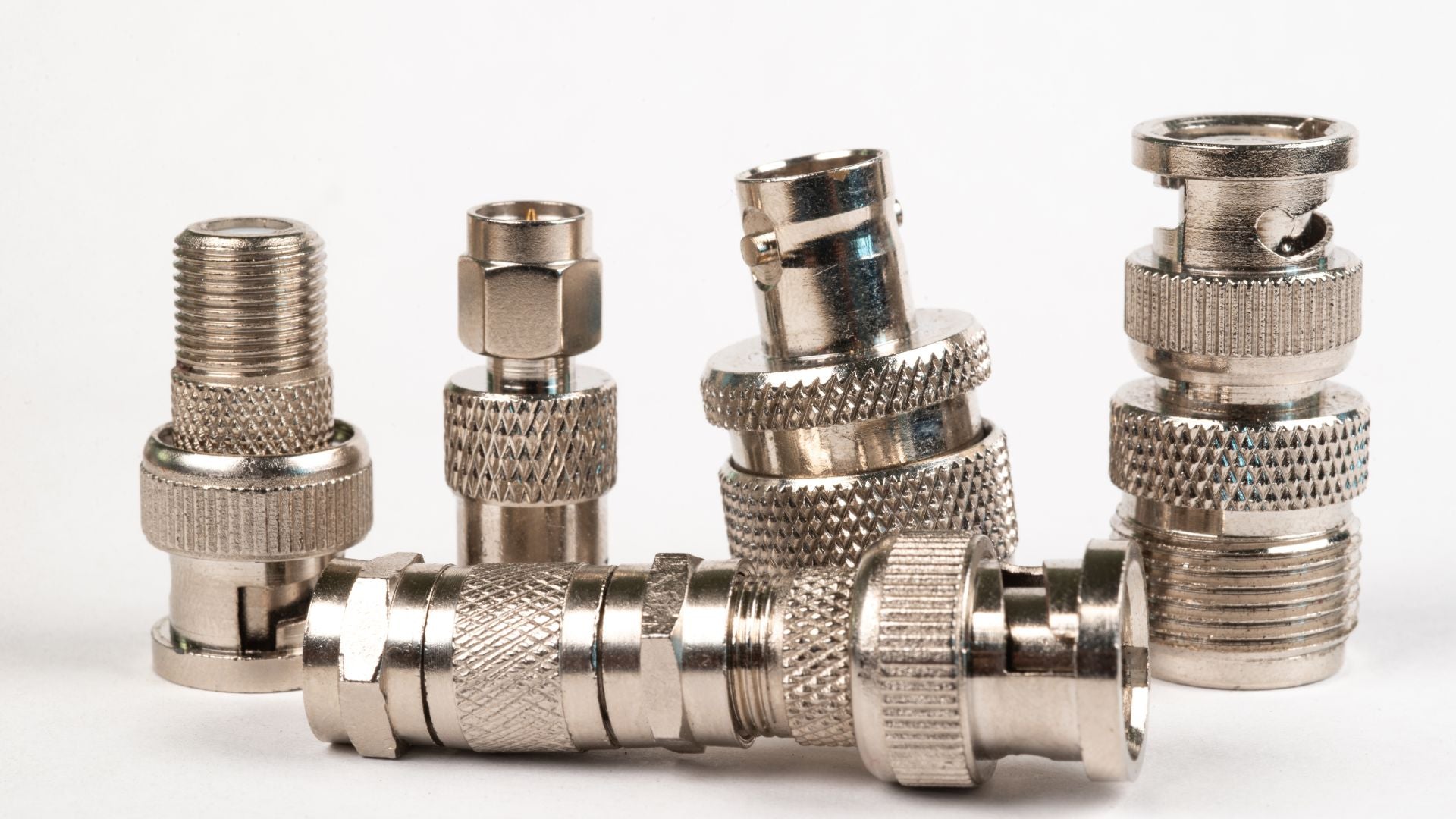

Nickel Plating

Nickel plating can give an attractive finish to your parts. However, sometimes it can be an expensive pursuit when using industrial finishers to electroplate just a few small parts - So why take the risk? Youplate offer industrial grade products which give top quality finishes at home.

How to Nickel Plate

Preparation is key! Ensure all work is stripped of paint, pre-existing electrodeposited metals and importantly all oils, greases and soils.

- Use appropriate stripping products for coating removal.

- Use a formulated, industrial grade cleaning product for the removal of oils, greases and shop soils.

You must ensure that all residues of cleaners or stripping products are thoroughly washed off. At this point you will se water "spotting" on unclean work, if this happens start again!

Do not allow the components to come into contact with bare skin.

You may wish to connect your components to wires before cleaning so that direct contact is avoided. These wires act as a conductor for the process as well as a method of moving the components from process to process,

What you need for your plating bath

- A vessel to contain the solution (Plastic bucket or tub that is deep enough to submerge all the components)

- A power supply

- Conducting cables/wires (Do not allow copper wire from positive (anode) power supply to be immersed in solution)

- A solution heater (A tropical fish heater is often enough)

- A method of agitating the solution (A fish tank air pump works great)

- Nickel Anodes

- A method of hanging your anodes and components into the solution ( A small piece of copper tube should do, just bend the ends to prevent it rolling around)

Nickel plating products

-

Passivates & Finish Protection

Passivate protectives for electroplated zinc.

Useful information:

Temperature

50-70 °C

Voltage

5-7 Volts (Current should take care of itself)

The required current for effective plating should work out at 40amp/ft² of work in solution.

Time

Up to 30 mins

The time it takes to plate will depend upon what you are plating, the temperature, current passing through solution and solution electrolyte levels.

Disposal

As your solution is used, electrolyte constituents will be consumed. You may wish to maintain your solution or you may choose to start again. If you are disposing of spent plating solutions, please observe all GOV.UK regulations and dispose with care.

Bright nickel plating

Whilst many older parts that have been nickel plated were electroplated using a dull deposit and often hand polished, today we can achieve some really nice, bright results with a very simple kit.

A bright plating solution is made up in the same way as a standard base nickel solution, using all of the standard nickel plating salts. However, a bright plating solution has other, formulated products added to provide certain qualities which will help make the deposit more pleasing and importantly bright.

Each ingredient has a different role to play in the electroplating process and should be used to provide the best possible result.

Contact us

Whilst there is a lot of information available online, we will try not to overload users of this web site with information which may not always be needed, so if there is a question you may have regarding you electroplating, please feel free to contact us.